Industrial Equipment

Extraction system

Supercritical Fluid Extraction: SFE is a highly selective method using pressurized fluids as solvents. A supercritical fluid originates from a fluid being forced to pressure and temperature that is above its critical point causing the liquid and gas phases to become indistinguishable from each other.

Advantages of SFE

- Continuous and automatic production with very low idle and turnaround time

- High performance and secured technology

- No residue of CO2 in final product

- Investment in scCO2 is at low risk

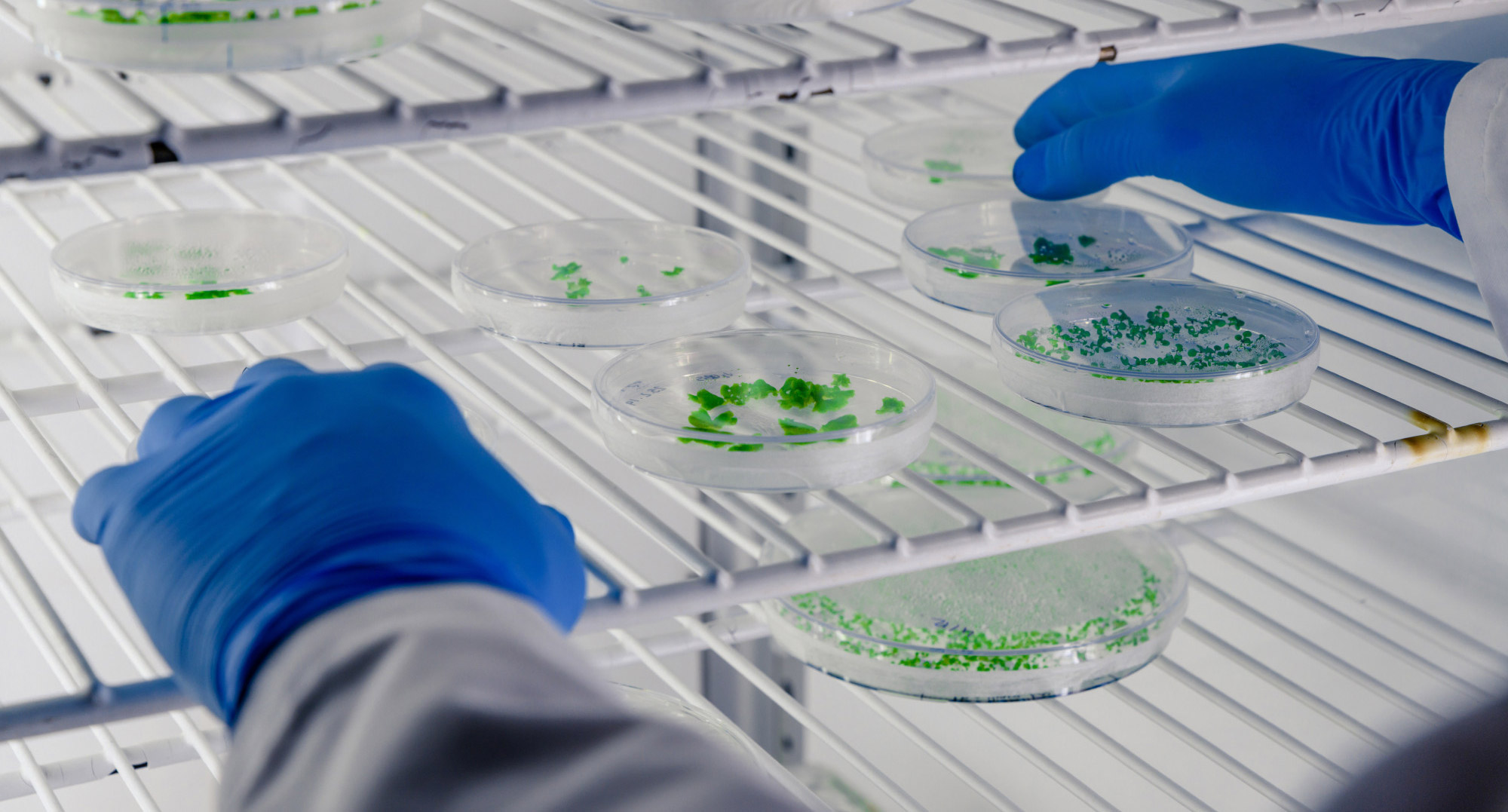

LABORATORY SCALE: SFE Lab

SIMPLE AND EFFICIENT STANDARDS LABORATORIES EQUIPMENT

SFE Process manufactures laboratories systems and equipment. SFE Process equipment offers high precision. We conceptualize and manufacture adapted and tailor-made equipment easy to use and sophisticated. SFE Process equipment are already used in clean rooms for medicine application. We have also designed extraction and fractionation equipment for universities to train students and searchers.

PRODUCTION SCALE: SFE PROD

PRODUCTION SYSTEMS FROM 2X5L TO 2X100L AND OVER

SFE Process conceptualise, design, and manufacture equipment from 2X5L to large scale units, adapted to needs and desired productivity. SFE Process equipment has considerable advantages:

- High yield of extract

- Quickly obtained

- Fully automated for easy operation,

- Sophisticated equipment with dedicated parameters control.

- Catch valuable extract thanks to the cold trap separation!

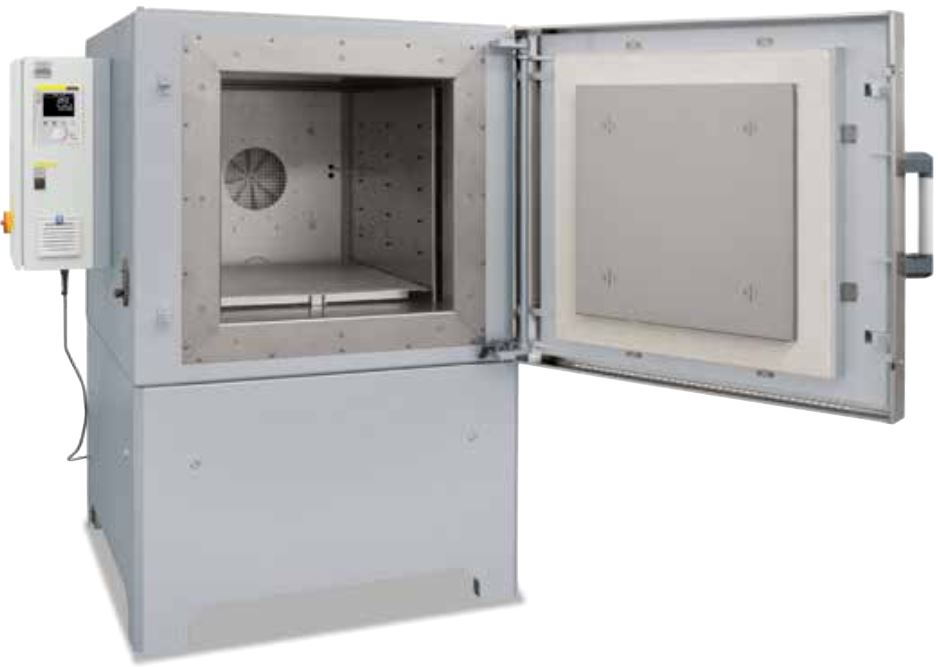

Furnaces: Nabertherm

Furnaces: Nabertherm

Nabertherm has been developing and manufacturing industrial kilns and furnaces for a wide range of applications for over 70 years. Professional engineering in combination with in-house production allows for the planning and construction of customer-specific thermal processing systems, tailored to the customer’s application.

Forced convection chamber furnace

Tub furnace

Bogie hearth furnace

Fiber optics/glass Fernaces

Nabertherm offers a wide range of products for the production of glass and fiber optics. From cooling/stress relieving of glass, to curing coatings to tempering quartz glass, you will find the right furnace model for your process with us.

Tilting furnace

Bale-out furnace

Crucible furnace

Foundry Fernaces

From electrically heated or gas-fired melting furnaces to dewaxing furnaces or core drying ovens to fully automatic quench and temper systems for aluminum or steel, we professionally cover the requirements of the foundry industry. Information on the furnaces for heat treatment can be found in Thermal Process Technology.

Chamber kilns

Top loaders

Fusing furnaces

Art & Crafts Fernaces

Whether for the hobby, schools, nurseries or for daily use in the professional ceramic workshop – we have the right kiln for you. Our range includes electrically or gas-heated kilns for pottery, glass or porcelain painting, for fusing or even for enameling.